MATRIX TOLL PATENTED

The Next Generation:

SCALEFRAC 880

Scale Inhibitors

General Information

In hydraulic fracturing, or fracing, scale inhibitors play a critical

role in ensuring the long-term success of the well. These

specialty chemicals prevent the formation of mineral deposits,

known as scale, which can clog up fractures and pipelines,

significantly hindering oil and gas production.

WHY ARE SCALE INHIBITORS

IMPORTANT IN FRACING?

Fracing fluids often contain dissolved minerals like calcium,

magnesium, and barium. When these minerals come into

contact with formation water or other injected fluids, they can

precipitate and form scale. This can occur due to changes in

temperature, pressure, or pH within the wellbore. Scale

build-up can have several detrimental consequences:

- REDUCED

FLOW: Clogged fractures

and pipelines

restrict the flow of

oil and gas, leading

to decreased

production rates.

- EQUIPMENT

DAMAGE: Scale can damage

pumps, valves, and

other equipment,

leading to costly

repairs and

downtime.

- FORMATION

DAMAGE: Scale deposits can

impede flow within

the formation itself,

hindering

hydrocarbon

recovery.

HOW DO SCALE INHIBITORS

WORK?

Scale inhibitors come in various forms, but they generally work

through one of two mechanisms:

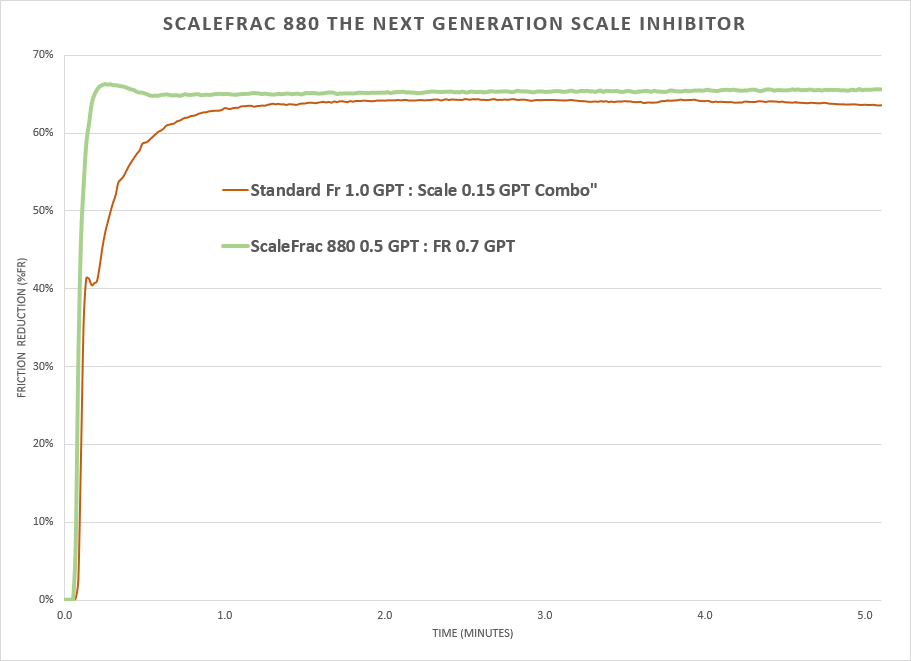

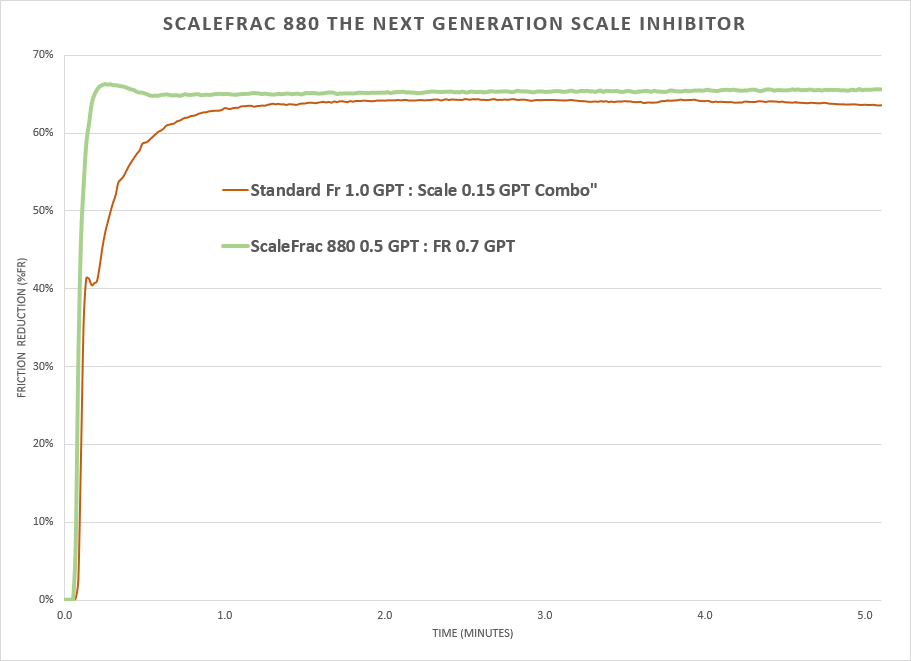

BENEFITS

OF USING

OUR NEXT GENERATION

SCALE INHIBITOR:

- LOWER FRICTION REDUCER CONSUMPTION BY 20%

- INCREASE FRICTION REDUCER PERFORMANCE BY

SUPPORTING HYDRATION

- LESS DEGRADATION TO FRICTION REDUCER OVER TIME

- ADVANCED BEYOND CONVENTIONAL INHIBITOR

PERFORMANCE

- LESS COLLOIDAL DAMAGE TO THE SHALE FORMATION

- LOWER VOCS FOR THE ENTIRE CHEMICAL PACKAGE

- DECREASE YOUR TOTAL COST TO TREAT

1000 GALLONS BY 10% TO 30%

- REDUCE HORSEPOWER CONSUMPTION

- ENVIRONMENTALY FRIENDLY

- INCREASE BPM

*Chart showing the difference between standard Fr's and The Next Generation ScaleFrac 880.

CHOOSING THE RIGHT

SCALE INHIBITOR

Selecting the most effective scale inhibitor for a specific fracing

operation depends on several factors, including:

- The type of minerals present in the formation water and fracing fluid.

- The type of minerals present in the formation water and fracing fluid.

- The compatibility of the inhibitor with other fracing fluid components.

ENVIRONMENTAL CONSIDERATIONS

The use of certain scale inhibitors in fracing has raised concerns

about their potential environmental impact. Some inhibitors, for

example, may degrade into harmful by products or persist in the

environment for long periods. Therefore, choosing environmentally

friendly scale inhibitors is essential for responsible fracing practices.

- MINIMIZED ENVIRONMENTAL IMPACT

- ABSENCE OF HARMFUL VOCS

- MEETS STRONGENT SAFETY STANDARDS